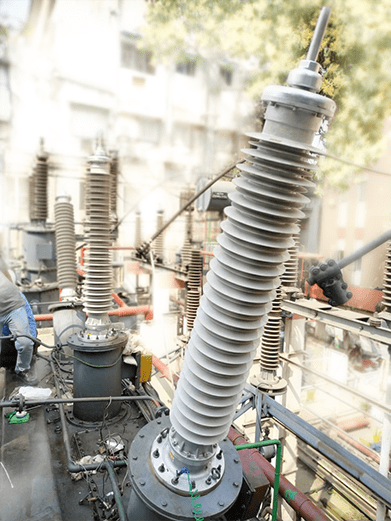

It is impossible to exaggerate how important it is to keep transformer bushings in perfect condition because even the smallest mistake can cause serious harm to the transformer and its surroundings. Transformer bushings are essential components, and at YASH, we specialize in providing flexible, custom-fit retrofit solutions for them.

Transformer bushings are our primary area of expertise, which enables us to provide a wide range of adaptable retrofit solutions. As a top provider of IEC/IEEE standard design bushings, YASH goes above and beyond to offer complete transformer bushing repair, replacement, and retrofit solutions from well-known international manufacturers. We handle flaws or damages in existing bushing components with accuracy and skill, regardless of the cause—years of operation, transit, handling, commissioning, or prolonged storage.

While other service providers concentrate on power transformer overhauls and repairs, YASH stands out for being the best at retrofit and repair solutions made specifically for transformer bushings. Transformer repair and overhaul companies, power substations, worldwide utilities, and EPCs have all recognized and awarded this specialization.

A committed group of knowledgeable Service and Retrofit Engineers who do not cut any corners make up our methodology. We guarantee a smooth procedure by doing thorough site evaluations, evaluating current products, examining old designs, and doing detailed engineering. We are dedicated to meeting our clients’ specific needs for interchangeability by working directly with them to develop identical interchangeable solutions.

Our mission at YASH is to maintain the longevity, safety, and dependability of transformer operations. Our goal is to provide customers with maximum transformer performance and peace of mind by utilizing our extensive knowledge of transformer bushings to provide creative retrofit solutions that surpass industry requirements and fulfill customer expectations.

Join forces with YASH for all-inclusive transformer bushing solutions that put the needs of your customers, accuracy, and dependability first. Get in touch with us right now to learn how our customized solutions can protect your transformer assets and improve their long-term operational effectiveness. Read more